It’s time to start with the airframe covering. Two types of fabric were considered: the high-end Oracover and the traditional widely used Dacron. First comes with impregnated dope and paint, and is very easy to install. Unfortunately it costs too much, so our choice is Dacron 1.8 oz fabric. For attaching the fabric to aluminum airframe we ordered EkoBond water based cement. Then nitrocellon will be used as a dope.

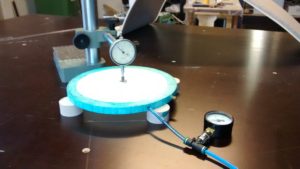

Such a setup should be tested first. For this purpose a ring made of plywood (outer dia = 240 mm; inner dia = 200 mm) was covered with Dacron. From the side a tube with a charge valve and a pressure gauge was installed. First we were interested in porosity capabilities of lacquered Dacron depending on the number of nitrocellon layers applied.

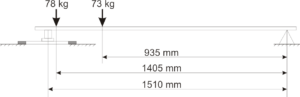

During the test the part was pressurized with air so that the maximum vertical deflection of the fabric is 3 mm. For precise detection of deflection a micrometer was used. The elapsed time until the deflection drops back down to zero was measured.

We got the following results:

| Pressure / deflection drop time, hh:mm:ss | ||||

| Nbr of layers | #1 | #2 | #3 | Average |

| 1 | 00:02:53 | 00:02:55 | 00:02:52 | 00:02:53 |

| 2 | 00:33:35 | 00:32:50 | 00:30:07 | 00:32:11 |

| 3 | 01:48:00 | 01:45:00 | 01:44:00 | 01:45:40 |

The conclusion is that the porosity is satisfactory already with two layers of nitrocellon.

Next task was to test the strength of the fabric. It became evident that with very large deflections (>30 mm in the present setup) the cellon become brittle and the porosity increases. For this reason we were unable to do the destructive pneumatic pressure test, but there were no obstacles to destroy the fabric mechanically.

It turned out that the Dacron 1.8 oz fabric can withstand pressure of 6 bar!