Stainless steel cables (7×19 AISI316 wire ropes) in Goat serve for two purposes:

- airframe stiffness assurance;

- flight control surface actuation.

Airframe cables are exactly the same as used in original Sandlin’s Goat design: four diagonal cables for each wing, two front cables for nose-wing connection and two rear cables for tail-wing connection. These are 2.5mm diameter cables.

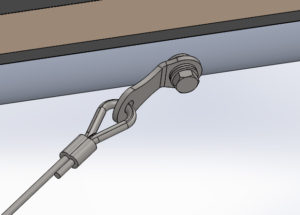

Flight control cables substitute the original rope solution for UV resistance and rigidness. 2mm diameter cables are used for elevator and rudder controls and are routed through pulley systems distributed throughout the airframe. Four turnbuckle assemblies are used to connect nose section control cables with tail section cables.

Regardless of the cable type all cables share the same type of connection. The link between cable and structure or control element is a stainless steel cable tang (bent or straight). Cable is attached to the tang using a cable thimble and a nicopress sleeve.

For manufacturing of cable assemblies we used a table surface with one fixed and one adjustable hole to fix the thimbles of both ends of the cable assembly according to cable length derived from CAD drawings. The cable is then routed through the thimbles, and sleeves are pressed using a swaging tool (Aircraft Spruce P/N 12-12000).